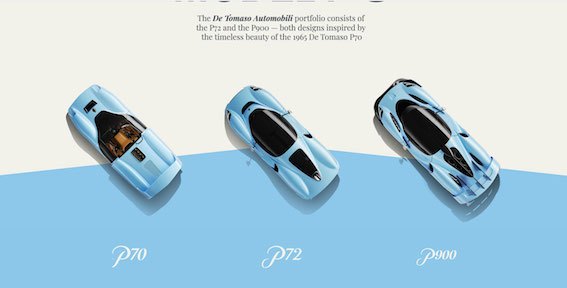

A Milestone In The Making: P72 & P900 Enter Production

De Tomaso Automobili is thrilled to announce the commencement of production for the much-anticipated P72 & P900 platforms. Over the past year, our teams have meticulously re-engineered each carbon chassis, culminating in two stunning final iterations that showcase our dedication to engineering excellence and hand craftsmanship. For The RoadThe P72 features an innovative unibody design, crafted with a performance-driven ethos and an unwavering commitment to safety. The chassis, composed of multiple layers of directionally hand-laid carbon fibre, offers unparalleled rigidity and a stunning visual appearance, highlighted by its intricate 4×4 weave pattern. This masterpiece of carbon engineering not only reflects our brand’s relentless pursuit of perfection but also serves as a testament to De Tomaso’s enduring heritage. For The Track

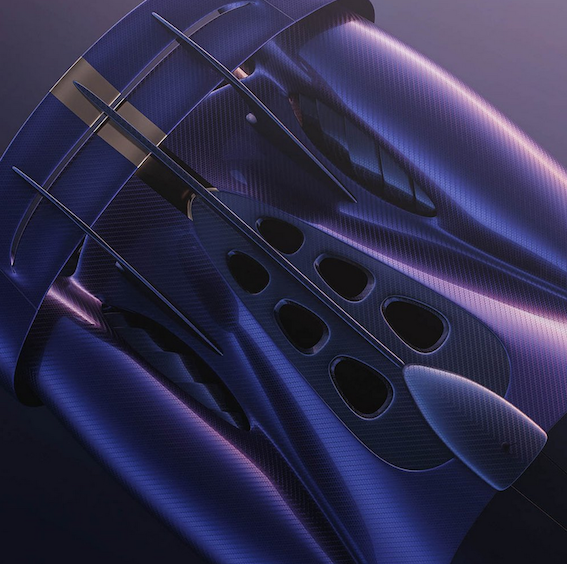

We are equally proud to introduce the P900 monocoque, a marvel of engineering that pays homage to our storied racing legacy. This chassis, equipped with an integrated roll cage, ensures maximum safety for high-intensity track experiences. It has been meticulously lightened and refined to meet the rigorous demands of racing regulation, empowering our esteemed custodians to explore the full potential of De Tomaso’s engineering prowess. Stay tuned as we unveil further details on the P900 in the coming months.

Hand-Assembled Excellence

In keeping with our commitment to quality, each P72 and P900 will be hand-assembled by a dedicated team of four skilled artisans, investing a total of 1,600 hours into every vehicle. As we approach the release of the first batch of these exceptional machines later this year, we are fully immersed in the final stages of evaluation, ensuring that every detail meets our exacting standards.

In Summary

Throughout this journey, De Tomaso has adhered to a rigorous quality control process, aiming to deliver vehicles that embody the visionary spirit of our initial concept. As we near the ‘end of the beginning,’ we extend our heartfelt thanks to our loyal supporters for their unwavering encouragement and passion. The P72 and P900 are more than just automobiles — they are the embodiment of our dreams and dedication, soon to be realized.

An All-New Chassis For 2024

As we embark on a new year filled with promise, we are delighted to share with you the latest developments from our heart of operations in Affalterbach, Germany.

Our journey toward realizing the production specification of the P72 has been a labor of love spanning several years of intense development. This year, we are proud to announce that assembly preparations are well underway for the preliminary series of European builds. In the midst of anticipation, we are sharing with you our final iteration of the production-ready monocoque design and suspension geometry for the P72.

Unique Unibody Design

Over the past year, we have embarked on a journey to unify the key structural components of the P72, merging the glasshouse and outer shells to create a true marvel of engineering. Our unibody, single-tool approach is cutting-edge and significantly improves the longevity of the vehicle’s underpinnings. With zero connecting joints or adhesive bonding, further weight savings, and occupant safety optimizations, the latest and final iteration of the P72 monocoque boasts a unique, singular, and continuous form – a marvel of carbon fibre craftsmanship.

Ergonomic Enhancements

In response to feedback from custodians who have experienced the pre-production cars, significant ergonomic changes have been implemented by optimizing the interior surfaces. Custodians will now benefit from an expanded interior cabin, thanks to an 80 mm reduction in the driver’s seating position, providing additional legroom and enhancing overall driver comfort. Additionally, after thoughtful consideration of custodian feedback, our teams have diligently engineered a notable 120 mm reduction in the sill height for production, improving the ease of entry and exit to the vehicle.

Improved Saftey Measures

Significant attention has also been devoted to safeguarding the core structure of the monocoque during minor collisions. We have now introduced an all-new carbon fiber bumper on the front crash structure, providing additional cross-bracing with a tubular design to facilitate a linear flow of forces. Similarly, the rear crash structure has been noticeably enlarged to improve stiffness and fitted with an additional low-impact retaining bar, providing maximum protection for the monocoque in the event of a light collision.

Optimized For Road Compliance

In the suspension department, extensive track testing demonstrated the maturity of our design under aggressive driving conditions. Yet, the dual nature of the P72 demands a refined approach to road dynamics, melding characteristics of both road and race cars. With dimensional enhancements to the vehicle’s core structure, a complete redesign of the suspension became imperative to align with new mounting points and desired road-driving capabilities.

As our first priority, De Tomaso engineering teams have once again expanded the overall dimensions of the upper and lower wishbones, resulting in notable enhancements to road compliance, longevity, and mechanical grip. Included in this change, we initiated a thorough overhaul of the double wishbone packaging to improve lateral grip during aggressive driving and reduce camber gain in the corners. Overall, our latest suspension geometry represents the culmination of years of motorsport experience, condensed into a package that excels both on the road and on track.

Hardware Updates

Consistent with this ethos, our teams took the decision to upgrade the suspension bearings to fully sealed derivatives sourced from the latest GT4 race cars. These enhancements guarantee seamless suspension operation in any weather, with a keen focus on maintaining the system’s durability. As a result of our geometry refinements, the vehicle now boasts significantly improved balance both front and rear, instilling an unparalleled sense of encouragement and confidence when conditions allow for spirited driving.

Furthermore, our new layout facilitates an improved packaging of the steering rack and ensures exceptional performance even under bumpy conditions or high loads. Integrating a design derived from LMP race cars, our fully hydraulic evolution now boasts the smallest possible turning radius achievable for the P72. Finally, the connection mechanism has now been optimized, seeing a reduction from three to two universal joints, resulting in a more direct feel and predictable linear behaviour.

In Summary

The past year of development has led us down a new path of discovery as we tackled the many challenges of packaging the P72 for road homologation. We trust that the additional development time will result in a sense of fulfillment for the project, yielding a significantly enhanced end product in terms of driving dynamics and overall vehicle safety. Above all, we eagerly anticipate the commencement of P72 production in the second half of this year.

READ ALSO: